The automotive rectifier bridge structural component is primarily an electronic device that converts input alternating current (AC) voltage into direct current (DC) voltage. It consists of multiple rectifier diodes (usually) encapsulated within a housing. In automobiles, the main function of the rectifier bridge is to ensure the stability and reliability of the power circuit, especially when involving AC-to-DC conversion.

Rectifier bridges typically come in two main types: half-bridge and full-bridge. A full-bridge rectifier contains four diodes that are connected in a bridge configuration, allowing for the complete conversion of incoming AC voltage to DC voltage. On the other hand, a half-bridge rectifier consists of two diodes, often used to form a full-wave rectification circuit with a transformer with a center tap.

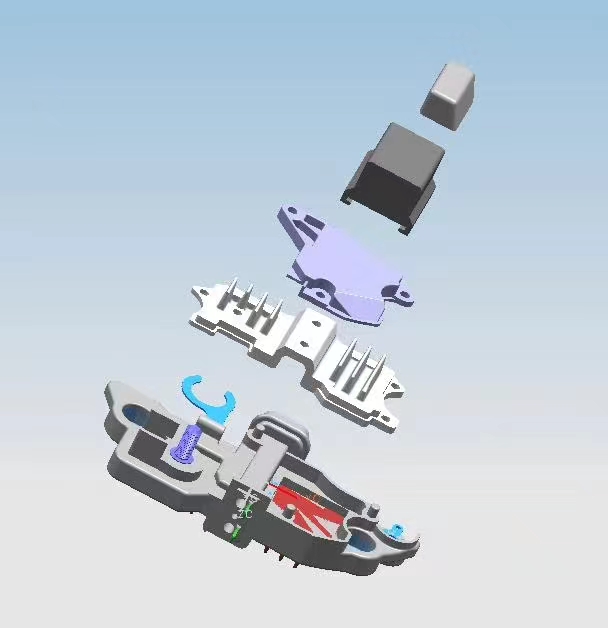

These diodes work in a specific arrangement within the rectifier bridge, ensuring that only some diodes are active during each work cycle, achieving the conversion from AC to DC. Additionally, the rectifier bridge structural component includes auxiliary structures such as heat sinks and pins to enhance its operational efficiency and stability.

Overall, the automotive rectifier bridge structural component is an integral part of the vehicle's power system, ensuring a stable power supply and thus the smooth operation of the automobile's electrical system.